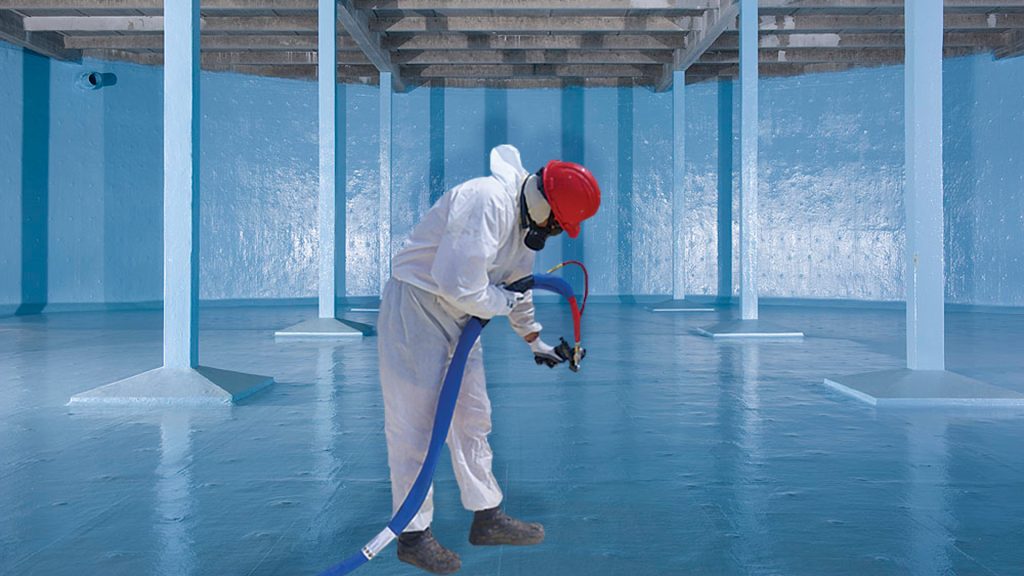

Polyurea coatings combine extreme application properties such as quick cure and insensitivity to heat, with exceptional physical properties such as high hardness, flexibility, tear, and tensile strength, as well as chemical and water resistance. This results in good weathering and abrasion resistance. The systems are 100% solids, making them compliant with the strictest VOC policies. Due to its particular curing profile and extraordinary film properties, the polyurea spray coating method has been presented into lots of properties, consisting of rust protection, containment, membranes, linings, and caulks.

Definition:

A polyurethane coating results from a response between an isocyanate element and a resin mix made with just hydroxyl-containing resins. The final coating property will consist of no intentional urea groups. A polyurethane system will most probably contain several catalysts.

A polyurea coating is the outcome of a one-step reaction between an isocyanate component and a resin-blend element. The isocyanate can be monomer based, a prepolymer, a polymer, or a blend. For the prepolymer, amine- and hydroxyl-terminated resins can be utilized. On the other hand, the resin blend ought to only contain amine-terminated resins and chain extenders and not any hydroxyl reactive polymer elements. All the polyurea coatings discussed in the paper abide by this requirement.

A polyurethane/polyurea hybrid coating has a structure that is a mix of those two-coating systems. The isocyanate element can be the same as the “pure” polyurea systems. The resin mix is a blend of amine-terminated and hydroxyl-terminated polymer resins and chain extenders. The resin mix might likewise include additives or non-primary elements. The addition of several drivers is needed to bring the reactivity of the hydroxyl-containing resins to the same level of reactivity as the amine-terminated resins.

The water/isocyanate reaction also produces urea-groups at the end of the procedure. Nevertheless, this reaction should not be considered a polyurea response as the mechanism is a two-step process controlled by the much slower isocyanate water reaction and produces carbon dioxide.

The Polyurethane Landscape

The option between the various polyurethane (PU) technologies is based on different criteria (Figure 2). Polyurethane provides the best compromise between expense and quality; however, it is limited by application efficiency. The polyurethane system is vulnerable to blistering when the substrate includes more than 5% humidity. This is because of competitors between hydroxyl-polyols and water for the response with an isocyanate group. The humidity content of the environment and the application temperature level limit aspects for polyurethanes and other chemically responding systems.

Hybrid systems currently have a bigger scope for application conditions. However, drivers’ existence in hybrids makes them more sensitive to humidity than “pure” polyurea systems. Furthermore, because the catalyzed polyol/isocyanate reaction behaves differently from the amine/isocyanate response to altering application temperatures, the system becomes less robust.

Polyurea can be utilized in extreme conditions. When it is utilized on substrates practically saturated with water, polyurea will not provoke blistering, nor will blistering occur when the air contains high quantities of humidity. Even at low-temperature levels (as low as -20 deg C), the polyurea coating will still cure. Polyurea coatings combine high flexibility with solidity. They are the most suitable coatings when the following is needed:

high treating speed;

an application under high humidity and at low-temperature levels;

severe abrasion resistance;

impermeable membranes;

high thickness build up;

chemical resistance.

Applications for Polyurea Coatings

Good knowledge of the characteristics of polyurea spray coatings is required to specify the right application. Table 1 provides a general overview of the physical and chemical properties expected of polyurea spray products. Polyurea systems are understood to be extremely hard. They integrate high elasticity with high surface area firmness, resulting in great abrasion resistance.

The marketplace advancement started in the United States, followed by Asia, with very strong growth during the 2nd half of the 1990s. In the first stage of development, polyurea was utilized as a protective layer over polyurethane insulation foam for roofing applications. In Europe, the polyurea spray coatings market only began to establish in the last couple of years.

The broad window of application conditions, with a high tolerance for humidity, both from the environment and from the substrate and temperature level, makes polyurea a very suitable coating for concrete in construction applications such as roof repair work, containment liners, membranes, parking area decks, bridges and offshore. The high abrasion resistance causes its application in liners for truck, bulk transportation wagons, freighters, and conveyor belts. Table 2 presents a summary of the application fields where polyurea is picked based upon one or more of its specific application and movie properties.

Raw Materials

A polyurea spray coating formulation consists of five aspects: the isocyanate component, (reactive) diluent, polyether amines, chain extenders, additives, fillers, and pigments.

Isocyanate

Considering that the most commonly used isocyanate is diphenylmethane diisocyanate (MDI), this paper focuses on MDI-based products. Aliphatic systems can be utilized where UV stability is an issue.

Standard polyurea spray coatings utilize MDI prepolymers with an NCO material of 15 to 16%. In this NCO variety, a great compromise between the product’s viscosity and the reactivity of the system is gotten. Lower-NCO prepolymers have a higher viscosity but provide greater flexibility and slower reactivity. Higher-NCO prepolymers are lower in viscosity, which provides an efficient mixture of the two components. Nevertheless, they become much more reactive, with the risk of developing more internal tension. Higher-NCO prepolymers will be used if greater surface firmness is needed. Table 3 introduces the primary residential or commercial properties of the MDI prepolymers used for polyurea spray coatings in Europe.

Diluent

JEFFSOL( r) PC, or propylene carbonate, is a reactive diluent for polyurea. Propylene carbonate has a high flash point, low toxicity, and should not be considered a volatile organic compound (VOC). The main benefits of using propylene carbonate are:

the enhanced life span of the isocyanate-prepolymer;

a compatibilizer for the mixing of the two elements in the mixing chamber of the spray gun;

a viscosity reducer for isocyanate-prepolymers;

improved leveling of the applied movie.

Propylene carbonate reacts with an amine to offer a carbamate structure consisting of a secondary hydroxyl group. Due to the quick response between isocyanate and amine, the secondary hydroxyl does not have the chance to respond with an isocyanate group. The propylene carbonate molecule should, for that reason, be thought about as a mono-functional particle (Figure 3).

In applications where contact with water can not be avoided, propylene carbonate should also be limited. As propylene carbonate is miscible with water, and unreacted propylene carbonate could be extracted, increasing the movie’s water permeability.

ArmorThane owns specific patents associating with using propylene carbonate in polyurea elastomers. Other solvents or viscosity reducers can be utilized if they are compatible with the isocyanate part. They may be considered as VOCs. However, they will increase the shrinking effect.

Polyether amines

The amine blend utilized in polyurea spray coatings is a mixture of polyether amines and chain extenders. The resin blend’s primary component is a mix of amine-terminated ethylene oxide and propylene oxide polyether with molecular weights varying from 200 to 5000 g/mole. The primary amine groups supply an extremely quick and trustworthy reaction with the NCO groups of the isocyanate component. Table 4 presents the residential or commercial properties of the polyether amines typically utilized in polyurea.

Chain Extenders

Diethyl-toluene diamine, or DETDA, is the basic chain extender utilized in fragrant polyurea spray coatings. DETDA adds to the difficult block and enhances the heat resistance of the cured film. It is the most reactive amine in the resin mix but, because of the stage separation throughout the treating, it manages the reaction system and makes it possible to spray a polyurea film.

Other chain extenders like dimethylthio-toluene diamine (DMTDA), N, N’- di( sec.butyl)- amino-biphenyl methane (DBMDA) or 4,4′- methylenebis-( 3-chloro, 2,6-diethyl)- aniline (MCDEA) decrease the reaction significantly. Table 5 lists different chain extenders and their characteristics. Significantly decreasing the reaction also implies that the competitors with the water reaction become more crucial, and safety measures require to be taken.

Additives, Fillers, Pigments

Depending upon the application, solvents, additives, pigments, and fillers are presented to the formulation. Adhesion promoters like silanes are used to boost the adhesion on steel and concrete. UV absorbers are utilized to slow down the yellowing effect of fragrant polyurea systems. Fillers are added to decrease the raw material cost and improve the physical properties of the coating. The addition of pigment and fillers is limited because the two parts’ viscosity at the application temperature level has to be kept under control. Higher quantities of fillers and reinforcement fillers can be contributed to the system as a 3rd part.

Product-Application Specifics

The most important component of managing polyurea coatings is blending. Great mixing will be gotten in a suitable blending module by impingement with the mechanical purge. The operational pressure and temperature of the items will likewise assist in optimizing the blending efficiency.

Due to the high remedy speed of polyurea and the short mixing time, the products are blended by impingement at high pressure. Undoubtedly, it is more suitable for field applications to create the products on a fixed 1:1 volume-mixing ratio. The pressure used in the field will vary between 150 and 250 bar. The viscosity of the items at application temperature preferably needs to be lower than 100 mPa.s, and the viscosity of the two parts requires to be at the same level. The properties of these prepolymers can be found in Table 3. The resin mix’s viscosity at 25 deg C is roughly 900 mPa.s, dropping below 100 mPa.s at application temperature level.

Experiments prove that polyurea movies produced at 65 deg C, 70 deg C, and 80 deg C have different homes, and these properties enhance with increasing temperature levels. The spraying devices have improved significantly. The new spray devices enable various temperature settings for the two components, guaranteeing a maximum mixing in the spray head. Other functions are simpler variable-ratio settings, simple output control, and simple monitoring of application parameters.

The index of a polyurea system is generally kept at a minor over-index of the isocyanate in the variety of 1.05-1.10. As the isocyanate group responds to humidity, the excess isocyanate compensates for the ‘loss’ of isocyanate groups during storage and application. The film properties of the 1:1 volume ratio sprayed system were determined for an index variation between 0.90 and 1.15. The test results indicate that the film performs finest at an index of 1.05 and higher. Below an index of 1.05, the results can differ significantly and end up being unforeseeable, even for little index shifts.

Elements of Spray Polyurea Technology

Polyurea applications had some issues during the initial start-up stage, which are at the origin of the still-existing mistaken beliefs about polyurea technology. These problems can be associated partially with the lack of experience at the technology intro, partly due to the absence of adequate application equipment, and partially to the truth that this new technology could not be applied in the same way as the current coatings systems.

Initially, polyurea spray coatings looked too simple to apply. Polyurea is extremely fast – the coating can be taken into service right away after the application. The final homes of the coating are acquired just a couple of hours afterward. Polyurea is not water- or temperature-sensitive and is easy to formulate and produce. The first systems on the market were indeed really quickly, with a gel time of fewer than two seconds, and at first, a variety of issues were linked to the reactivity of the systems.

In the beginning, substrate wetting was a problem. This problem was connected to the advancement phase of polyurea with the use of incredibly quick spray systems. Development programs focusing on adhesion on concrete, with polyurea systems presenting gel times of 3 to four seconds, led to cohesive adhesion failure in the concrete. In practice, to restrict the dangers under variable field conditions, a multi-layer system is applied, made from a guide and an overcoat.

A second problem kept in mind in the field was the lack of inter-coat adhesion. Lab tests, with times in between coats of numerous weeks, have revealed that inter-coat adhesion is very good. When issues occur with inter-coat adhesion, the majority of the time, they can be related to the raw products, the production of the systems, or the spray devices. Spray devises issues, or a disruption of the feeding of one or both elements towards the mixing module can trigger bad blending. Adapting the machine settings of the spray can solve this.

Due to the systems’ high reactivity, the surface quality of the sprayed movie was initially extremely bad. Tweaking the spraying devices was a first step towards fixing the problem. Making use of non-VOC reactive diluents and the advancement of new MDI prepolymers with greater 2,4′- isomer material led to ideal surface area quality without compromising on working time.

The cost of polyurea spray coatings technology is seen as a barrier to entry. “Pure” polyurea systems are more costly when thinking about basic materials expense alone; however, it can be applied in locations where all other systems will stop working or where they are not suitable. Likewise, the preliminary investment in equipment is rather expensive.

However, when estimating the capital cost for a task, polyurea is more competitive when both the processing time and the waiting duration before the covered substrate is returned into service are included.

As discussed above, the project’s success is equipment- and applicator-dependent, and we believe that the high entry barrier can only guarantee quality services from specialized and proficient operators.

Construction-Related Aspects

Polyurea spray coatings can be used under hard weather since the chemistry is extremely fast, and they do not experience unfavorable side effects triggered by humidity. They also cure at temperature levels below 0 deg C. However, when using polyurea coatings, several preventative measures still need to be taken.

If guides are considered, an excellent method is to examine existing primers with known performance on the substrate. It is necessary to identify the adhesion performance of the polyurea coating on the primers and inspect whether the guide’s application conditions and the re-coating conditions for the primer still work for a system with polyurea as a finish.

Concrete Surface Defects and Surface Preparation

The low cost, high strength, and structural properties of concrete make it the product of the construction industry’s option. Some of the normal concrete homes, like the minimal chemical resistance, dust release, and porosity or permeability, make it necessary to put a protective and ornamental layer onto the surface.

The preparation of the surface area is exceptionally essential. Depending on the surface area quality of the concrete, one or more of the following actions needs to be taken:

The water jet and solvent cleaning;

Grit blasting;Bunghole and fracture filling;

Repair layer of concrete;

priming.

Steel Surface Defects and Surface Preparation

The life cycle of steel construction coatings depends mainly upon the protective system put in place. The life of the protective coating itself is strongly dependent on the surface condition before applying the coating. The protection of the substrate is generally obtained by ensuring excellent adhesion. 2 adhesion mechanisms are possible:

- Molecular destination of the interfacial forces from both the coating and the substrate.

- Mechanical bonding or anchoring of the coating on the substrate.

Depending on the surface’s condition, one or more of the following pre-treatments will be required: cleansing and degreasing with solvents, water jet or cleaning agents; hand or power-tool cleaning; grit blasting.

On newly grit-blasted, dust-free steel with a surface area roughness SA 2 1/2 to SA 2 according to the specification ISO 8501-1, extremely high adhesion values can be obtained for polyurea, even without using guides.

Mixing Efficiency

The mixing efficiency of the application devices is of vital importance. When developing a system or customizing an existing system, it is needed to continuously verify the mixing efficiency. The above graph shows the influence of altering the mixing on the physical properties of a developed product. The tensile strength almost doubles from 14 N/mm2 to 23 N/mm2; the angle tear increases from 75 N/mm to 85 N/mm, and the elongation increases from 390 to 430 percent. In this case, the impact on other physical properties is restricted.

System Index Influence on Final Film Properties

Earlier experiments reveal that a polyurea coating must be formulated at an index above 1.00, indicating a somewhat greater amount of isocyanate-groups than amine-groups. At an index of 1.00 or lower, the physical homes of the coating become unreliable. Figure 5 shows that many residential or commercial properties have very good worths at indexes from 1.10 to 1.30. Above an index of 1.30, the efficiency tends to drop again.

Considering that, in practice, small variations might take place in the application criteria related to the accuracy of the spray devices and variations in application conditions, it is much safer to operate at a minimum index of 1.10 to 1.15.

Filler Influence on Physical Properties

Adding fillers to a polyurea system can be useful for different reasons, such as decreased raw product cost or enhancement in physical homes. Inorganic fillers have various hardness, and some will irritate parts of the spray devices more than others. The most delicate parts are the blending chamber and the nozzle of the spray gun. The filled systems need to be carefully filtered before product packaging.

The dosing of filler can differ depending upon the efficiency of the spray installation. We added up to 40% of filler to the resin mix. The main limiting aspect of the processing is the increase in the viscosity of the filled component. Due to big distinctions in both parts’ viscosity, this can lead to troubles with the pumping unit and poor mixing.

Adding fillers improves the surface area firmness, the angle tear, and flexural flexing modulus but has an unfavorable impact on the elongation and the tear propagation or trouser tear (Figure 6).

Water Absorption

For rust protection, the main consideration for good performance is adhesion to the substrate. More testing showed that, even with great adhesion, the resistance to cathodic disbondment for some systems stops working. Since cathodic disbondment happens over a longer-term and certainly is not an easy test approach, we measured the water absorption over ten days at 80 deg C and included 3% sodium chloride in the water.

As shown in Figure 7, the unmodified standard polyurea spray coatings provide minimal protection against corrosion. The water absorption drops significantly with increasing the NCO-content for the prepolymer. More fine-tuning of the prepolymer resulted in water absorption being well listed below 0.5% after ten days. Cathodic disbondment testing on this system offered very satisfying test outcomes.

Antiskid Performance

Flooring, car parks, and sports floors are key applications for polyurea due to its high abrasion resistance, great mechanical homes, and insensitivity to blistering during the curing process in humid conditions.

One example is the outside, impact-absorbing playground flooring. The system tested is based on SUPRASEC 2049, developed to be used in a 1 to 1 volume ratio. The film’s residential or commercial properties are 70 Shore A solidity, 600% elongation, and 13 N/mm2 tensile strength. The lead to Table 6 shows that it is perfectly possible to develop a system, which complies with a flooring system’s antiskid needs, in this case, for a flexible substrate.

Conclusions

Polyurea spray coating technology is different from other coating chemistries and can expand the application range of coatings to areas and conditions where other coating systems will stop working.

Polyureas are ideal for construction applications. Their fast curing makes them possible to use when only extremely short disruption durations are enabled. The isocyanate/water reaction does not impact the physical properties of the used film, expanding polyurea to high relative humidity conditions. It does not set such stringent limitations on the water material substrate concrete. Although they slow down at chillier temperatures, polyurea coatings still treat temperatures where other chemicals stop working.

The formulation of polyurea spray coatings has to be approached similarly to any other coating system. Careful choice of basic materials for fine-tuning the formulation and assessment of the system is still required, especially in difficult conditions where the coating is to be used.

Polyurea spray coating technology suggests handling reactive chemicals. While managing the chemicals during their production, packaging, and application, the appropriate protective clothing should always be used.

Special Thanks:

The author wishes to thank ArmorThane for applying and testing the polyurea samples, Hank Strathman for supporting the systems’ testing, and all other ArmorThane personnel who assisted in realizing this paper.