Understanding the Different Types of Professional Protective Coatings & What They Are Used For

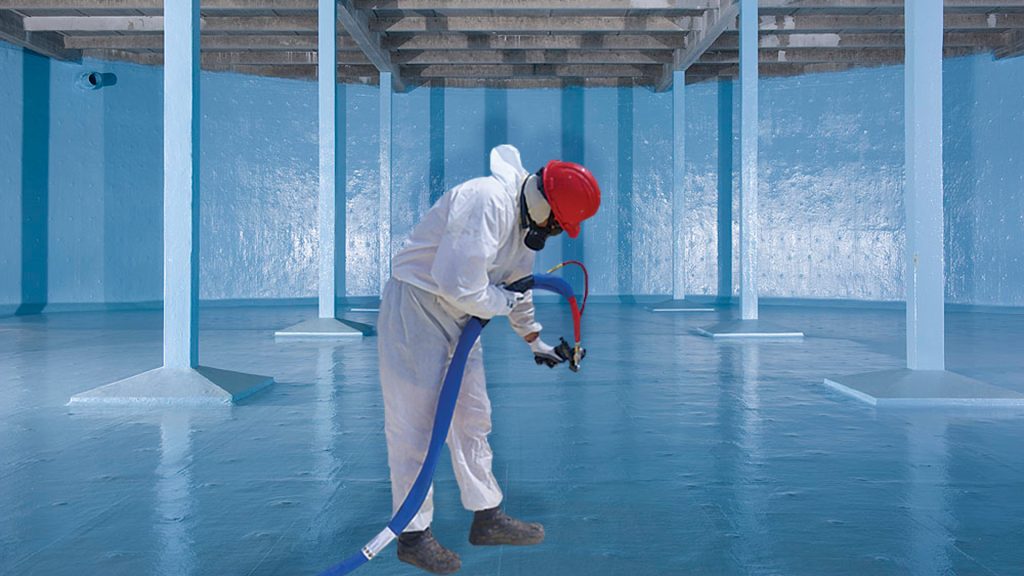

Protective coatings are special materials applied to the surface of an object or structure to protect it from damage, corrosion, and wear. Professional protective coatings come in a variety of forms, including organic, inorganic, and elastomeric. Each type has its own advantages and disadvantages and is used for specific purposes.

Organic coatings are those made from a variety of compounds, such as polymers, resins, and oils. They are typically used for decorative and aesthetic purposes, as they tend to be more attractive than other types of coatings. Additionally, they offer protection from UV rays, moisture, and chemicals.

Inorganic coatings, such as zinc and aluminum-based coatings, are more durable than organic coatings and provide superior protection from corrosion. These coatings are often used in industrial and marine applications, as they are able to withstand extreme temperatures and harsh conditions.

Elastomeric coatings are made from rubber or plastic-based materials, making them flexible and elastic. They are commonly used in roofing, as they are able to expand and contract with the movement of the roof. Additionally, they can provide a protective barrier against water, UV rays, and other environmental factors.

No matter the type of coating used, professional protective coatings provide a variety of benefits, such as improved appearance, increased durability, and enhanced resistance to damage and corrosion. Furthermore, they can help reduce maintenance costs, extend the life of the material or structure they are applied to, and provide a safe, healthy environment.

What to Consider Before Making a Final Decision on the Protective Coating for Your Project

When it comes to choosing a protective coating for a project, there are a few important considerations to keep in mind.

First, it’s essential to understand the purpose of the coating. Is it intended to protect against corrosion, provide a decorative finish, or both? This will help you determine the type of coating to choose.

Second, you must consider the environment in which the coating will be used. Different coatings are designed to withstand different levels of environmental exposure and wear. Choosing the right coating can prevent damage to the underlying surface and extend the life of the coating.

Third, you must consider the cost. Different coatings can vary significantly in price, so it’s important to select a coating that fits within your budget.

Fourth, you should consider the application process. Some coatings require specialized application techniques and can be difficult to apply if you don’t have the right tools and experience.

Finally, you should consider how long the coating will last. Some coatings are designed to last for many years, while others may need to be replaced more frequently.

By taking the time to consider each of these factors, you can ensure that you select the right protective coating for your project.

The Benefits of Professional Protective Coatings & Why They are Essential

Protective coatings are a critical component of any industrial or commercial setting, providing a key layer of protection for surfaces ranging from metal to concrete. These coatings help reduce corrosion and wear, improve the appearance of surfaces, and extend the life of the products they protect. As a result, it is essential for companies to invest in high-quality professional protective coatings.

The most common type of protective coating is a paint. A paint is a liquid that is applied to a surface to protect it from environmental elements. There are a wide range of paints available, from water-based to oil-based, and each type provides a different level of protection. Water-based paints are the most popular choice for industrial and commercial settings, as they provide superior protection against the elements. Oil-based paints are more resistant to chemical spills and are better suited to surfaces that are exposed to the elements.

In addition to paints, there are also a range of specialty coatings available. These include powder coatings, which are applied using an electrostatic process and provide a hard, durable finish. Other options include epoxies, which are used to provide a more permanent bond, and polyurethanes, which are often used to protect metal surfaces from corrosion.

No matter what type of protective coating is used, it is important to ensure that it is applied properly. Professional protective coatings can be applied by a professional with the right equipment and training. This ensures the coating is applied correctly, providing maximum protection and preventing the need for costly repairs or replacements.

The benefits of professional protective coatings extend beyond simply protecting surfaces. They can also reduce maintenance costs, as they are designed to last for years with minimal maintenance. Additionally, they can improve the aesthetic appeal of surfaces, making them more attractive to customers. Finally, they can also help reduce the amount of time needed for repairs or replacements, saving companies money in the long run.

In summary, professional protective coatings are an essential component of any industrial or commercial setting. They provide superior protection against the elements, reduce maintenance costs, improve the appearance of surfaces, and extend the life of the products they protect. Therefore, it is important for companies to invest in high-quality professional protective coatings.

How to Research and Compare Different Protective Coatings to Choose the Right One

Researching and comparing different protective coatings is a critical step in choosing the right one for any project. Different coatings have different properties that make them suitable for different applications, and it is important to understand the differences between them in order to make an informed decision. Here are some steps to help you research and compare different protective coatings.

- Identify your needs: Before beginning your research, it is important to identify the specific needs of your project. Consider the type of material you need to protect, as well as the environment in which it will be used. This will help you narrow down your choices and focus your research on coatings that are best suited to your needs.

- Research the options: Once you have identified your needs, it is time to begin researching the different protective coatings available. Learn about the properties of each type of coating, including its durability, abrasion resistance, chemical resistance, UV stability, and other features. Consider the cost of each coating and how it fits into your budget.

- Compare the options: Once you have identified the different coatings that may be suitable for your project, it is time to compare them. Consider how each coating meets your needs, and compare their performance in terms of strength, abrasion resistance, chemical resistance, UV stability, and other features. Consider the cost of each coating and how it fits into your budget.

- Make a decision: Once you have completed your research and comparison, it is time to make a decision. Take into account your needs, the performance of each option, and the cost of each option to determine which coating is best suited for your project.By taking the time to research and compare different protective coatings, you can ensure that you choose the right one for your project. With the right information, you can make an informed decision that will ensure the longevity and performance of your project.

Taking into Account Environmental Factors When Selecting a Protective Coating for Your Project

Selecting a protective coating for a project can be a complex task, as various environmental factors must be taken into consideration when making a decision. The environment in which the coating will be used can affect the performance, durability, and longevity of the coating. Therefore, it is essential to consider environmental factors such as temperature, humidity, abrasion, chemical exposure, corrosion, and UV radiation when selecting a protective coating.

Temperature is a critical factor to consider when selecting a protective coating for a project. Coating materials are designed to perform within a certain temperature range, and temperatures outside of this range could adversely affect the performance of the coating. Low temperatures can make the coating brittle and prone to cracking, while high temperatures can cause the coating to become soft and lose adhesion.

Humidity is another environmental factor that should be taken into consideration when selecting a protective coating. High humidity can cause the coating to absorb moisture, which can lead to corrosion or other damage. Low humidity can cause the coating to become brittle and prone to cracking.

Abrasion is also an important environmental factor that can affect the performance of a protective coating. Abrasive materials such as sand, gravel, or other debris can cause the coating to degrade and lose adhesion. Therefore, it is important to choose a coating that is designed to resist abrasion.

Chemical exposure is another environmental factor to consider when selecting a protective coating. Chemicals can react with the coating material, causing it to degrade or lose adhesion. Therefore, it is important to choose a coating that is designed to resist chemical exposure.

Corrosion is another environmental factor to consider when selecting a protective coating. Corrosion can cause the coating to degrade and lose adhesion. Therefore, it is important to choose a coating that is designed to resist corrosion.

Finally, UV radiation is an environmental factor that should be taken into consideration when selecting a protective coating. UV radiation can cause the coating to degrade and lose adhesion. Therefore, it is important to choose a coating that is designed to resist UV radiation.

By taking environmental factors into consideration when selecting a protective coating for a project, you can ensure that the coating will perform optimally in its intended environment. This will help to extend the life of the coating and protect the project from potential damage.