Polyurea is an long lasting material used to coat surfaces across different industries. Its properties make it suitable, for tasks like waterproofing, corrosion protection, insulation and soundproofing. The use of polyurea in coatings is on the rise emphasizing the importance of professionals having a grasp of the material before diving into becoming certified polyurea applicators.

Comprised of polyol and isocyanate components polyurea is a two part substance that gets mixed in a spray gun before being applied onto surfaces. Once applied it cures to form a bond with the surface. This material excels in adhering to surfaces such as metal, concrete, wood and plastic while showing resistance against chemicals, abrasion, impact and extreme temperatures.

The elasticity and flexibility of polyurea make it well suited for environments experiencing temperature fluctuations and movement variations. This flexibility helps safeguard surfaces from cracks and chips while its UV stability ensures color retention, under outdoor conditions.To become a certified polyurea applicator you need to meet safety, technical and application requirements. Safety measures include using gear, like respirators, goggles, protective clothing and gloves. Technical prerequisites involve understanding the material and its application process as having the right equipment and tools for the task. Application standards require following approved methods and techniques to ensure an effective application.

By mastering the fundamentals of polyurea professionals can earn certification as polyurea applicators. Confidently use this durable material for various applications. Polyurea can be applied to protect surfaces across industries due to its durability.

GETTING STARTED; THE ESSENTIALS OF PREPARING AND APPLYING POLYUREA

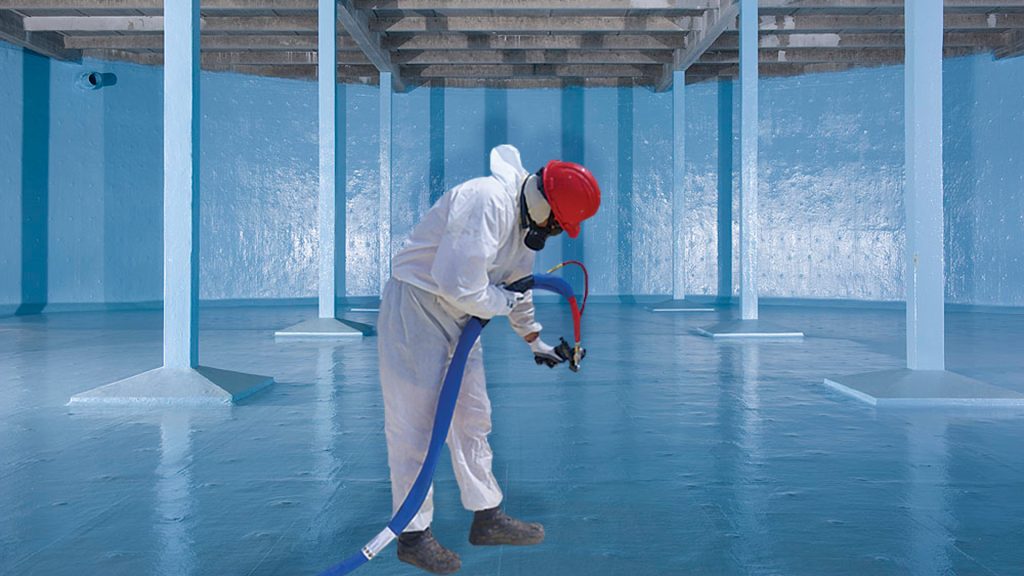

Polyurea serves as a coating for diverse applications ranging from automotive finishes to industrial flooring. Proper preparation and application of polyurea are essential, for achieving a top notch finish that withstands corrosion, abrasion and UV exposure.

Before starting the polyurea application process ensure that the surface is thoroughly cleaned and dry.

To start clean the area using a degreaser and a stiff brush to get rid of any dust, dirt or debris. Once the surface is clean use an industrial grade vacuum to remove any leftover particles. After ensuring the surface is completely clean and dry you can start applying the polyurea.

When applying the polyurea first mix the two components following the instructions provided by the manufacturer. Once mixed begin applying the material using a sprayer or roller. Ensure application and use a paintbrush to smooth out any areas.

After completing the polyurea application allow it to cure for the recommended duration specified by the manufacturer. Once cured you can add a topcoat, for protection. To enhance the finishs appearance.

By prepping and applying polyurea you can achieve a top quality finish. Create a durable surface that can withstand various conditions. With tools and materials on hand completing this task becomes manageable while reaping all the benefits of having a protective coating, in place.

Safety Precautions; What to Keep in Mind When Handling Polyurea

Polyurea is an valuable substance that finds applications. However it’s crucial to be mindful of safety precautions when working with this material.

First and foremost remember not to use polyurea in areas where theres a flame or any potential source of ignition. Being flammable it can easily catch fire in the presence of ignition sources leading to harm or even fatalities. It’s also essential to ensure ventilation, in the work area while dealing with polyurea as the fumes emitted can pose risks if breathed in amounts.

Moreover wearing gear like a face mask or respirator along with goggles is vital when handling polyurea. The substance can cause skin and eye irritation; hence minimizing contact and using protective equipment is crucial. Additionally it’s important to avoid inhaling the fumes produced during application since they can be detrimental to your health.

Lastly following the manufacturers instructions, for using the material is essential.

The material is specifically designed for uses. Using it in a way not recommended by the manufacturer can lead to unsafe or ineffective outcomes.

By adhering to these safety guidelines you can ensure that your utilization of polyurea remains safe and efficient.

GETTING THE GEAR; WHAT YOU NEED TO BECOME A POLYUREA APPLICATOR

For those aiming to excel in polyurea application having the appropriate equipment is crucial. While experienced professionals may already have some of the required tools newcomers might need to acquire supplies to complete the task successfully. Here’s a rundown of the items, for becoming a skilled polyurea applicator;

1. Respirator; When working with polyurea applications that involve spray guns producing fumes it’s vital to safeguard your health with an organic vapor cartridge respirator.

2. Protective Eyewear; Alongside protecting your lungs safeguarding your eyes from debris or particles generated during application is crucial. Ensure you have safety glasses or goggles for every project.

3. Protective Clothing; Since polyurea applications can get messy having clothing, at hand is important.

Wearing sleeves, pants and boots is advisable to protect yourself from any splashes or spills.

Sprayer; The key tool, for applying polyurea is a high quality sprayer that can handle the job. Look for models with pressures and variable speed settings.

Mixer; Before spraying it’s important to mix the two components required for polyurea applications thoroughly. A mixer ensures combination of ingredients for an application.

Hose and Fittings; To connect your sprayer to the air compressor you’ll need a suitable hose and fittings of the right size for your equipment.

Air Compressor; A compressor is essential to power the sprayer. Choose one that can provide pressure for your sprayer needs.

With the tools you can safely and effectively apply polyurea coatings. Investing in these items will help you master polyurea application quickly.

TIPS, FOR MAINTAINING YOUR POLYUREA COATINGS

maintenance is crucial to preserve the appearance of your polyurea coatings. Proper cleaning and care will ensure longevity. Keep them looking great for years to come.Here are some helpful tips, for cleaning and taking care of your polyurea coatings.

1. Keep it Clean; To keep your polyurea coating in condition make sure to clean it. Use a cloth or mild detergent at once a month. Avoid using water as much moisture can harm the coating.

2. Deal with Stains; If you notice any stains on your polyurea coating try using a detergent and warm water to remove them. For stains you may need to use a solvent following the manufacturers guidelines.

3. Safety First; When cleaning or applying a coat on your polyurea surface always wear gear like gloves, safety glasses and a respirator to ensure your safety.

4. Check for Damage; inspect your polyurea coating for any signs of damage or wear. If you spot any issues make repairs promptly to prevent damage and maintain its appearance.

5. Seal It Up; Applying a sealant is crucial, in preserving the look and durability of your polyurea coating.

By adhering to these suggestions you can safeguard the coating, from dirt, dust and moisture while also adding a shield, against UV rays.

With these guidelines you can maintain the appearance of your polyurea coatings for years ahead. Consistent cleaning and upkeep will preserve the quality of your coatings. Prolong their lifespan.