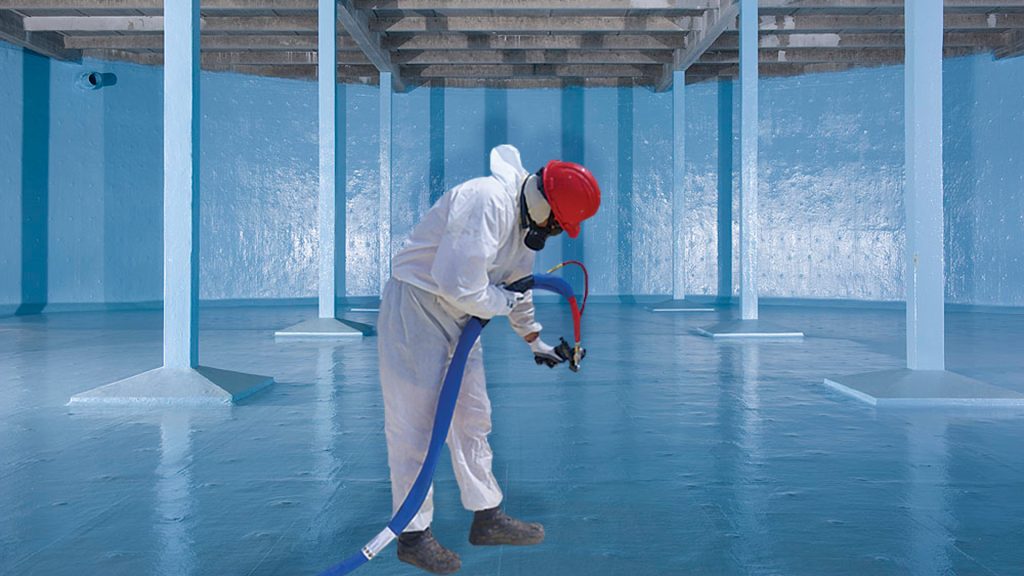

Polyurea is a cutting-edge protective coating technology highly valued for its strength, flexibility and quick drying features. It finds use, across industries for tasks ranging from ensuring waterproofing to enhancing resistance against wear and tear. This comprehensive guide delves into the world of polyurea, exploring its types, practical applications, and the distinct advantages it brings.

Understanding Polyurea

Polyurea represents a substance created through a reaction between an isocyanate component and a synthetic resin mixture using a process known as step growth polymerization. The end result is a coating that can be customized to suit specific performance needs while delivering unparalleled safeguarding against diverse environmental and mechanical pressures.

Varieties of Polyurea

Polyurea coatings can be broadly categorized into two types based on their composition;

- Pure Polyurea: This category consists entirely of polyurea chemistry, providing top-notch performance in flexibility, chemical resistance, and rapid setting times. Pure polyurea proves ideal for tasks demanding durability with operational downtime.

- Hybrid Polyurea: Hybrid formulations blend polyurea with substances like polyurethane. These coatings balance performance efficiency and cost-effectiveness, making them well-suited for applications where financial constraints play a role.

Top Benefits of Polyurea - Quick Drying; One major advantage of polyurea is its drying capability. Polyurea coatings can solidify within seconds, allowing for the resumption of operations without disruption.

Exceptional Strength: Polyurea offers protection against wear and tear impacts and chemical exposure. Its durability makes it ideal for environments with high usage. - Flexibility: The flexible property of polyurea enables it to fill cracks and adapt to substrate movements without compromising adhesion or integrity. This feature is crucial for structures exposed to temperature fluctuations.

Insights and Data Overview - Economic Influence: According to the Global Market Insights report, the polyurea market exceeded $600 million in 2020 and is expected to grow at a rate of 10% from 2021 to 2027. Rising industrial, automotive, and construction demand is driving this growth.

- Environmental Advantages: Research from the European Coatings Journal reveals that polyurea coatings can prolong infrastructure lifespans by up to 300%, significantly reducing the need for repairs and replacements. This extended durability leads to savings in material costs and environmental benefits.The research conducted by the American Society for Testing and Materials (ASTM), indicates that polyurea coatings can exhibit strengths of up to 4350 psi and elongation at break exceeding 500%. These figures underscore the characteristics of the material when compared to traditional coatings like epoxy and polyurethane.

Various industries benefit from the properties of polyurea in a multitude of applications.

- Waterproofing: The seamless and waterproof nature of polyurea makes it perfect for rooftops, foundations, and water containment structures, providing lasting protection against water infiltration due to its ability to withstand pressure.

- Industrial Flooring: Polyurea coatings offer a chemical-resistant surface for handling heavy traffic and exposure to harsh substances in industrial environments such as factories, warehouses, and chemical plants.

- Marine Coatings: Its resistance to saltwater and marine organisms makes polyurea a preferred choice for boats, docks and offshore structures. It serves as a shield against corrosion and biofouling, prolonging the life expectancy of assets.

- Automotive Usage: In the sector, polyurea finds applications in coatings, bed liners, and protective layers on vehicle parts. Its durability and impact resistance contribute to enhancing vehicle longevity and performance. Advancements in polyurea technology exploration and progress in polyurea technology result in formulations that tackle specific industry challenges. Some significant improvements include Antibacterial polyurea Formulations that prevent the growth of bacteria and fungi, making them suitable for use in healthcare facilities and food processing plants.

High-temperature-resistant Polyurea coatings are engineered to endure extended exposure to temperatures without deterioration, making them ideal for petrochemical purposes. - Environmentally Friendly Polyurea: Development of low VOC (volatile organic compounds) polyurea formulations that comply with strict environmental standards while maintaining exceptional performance.

In summary

Polyurea coatings signify a progression in protective coating technology offering durability, flexibility and fast curing times. Their application across sectors showcases their adaptability and effectiveness, in providing enduring protection. With technology advancing, the future of polyurea coatings appears promising, with innovations broadening their applications and elevating their performance levels.

Choosing to invest in polyurea coatings can result in infrastructure lifespan, decreased maintenance expenses and improved sustainability practices, positioning them as a component of contemporary protective solutions.