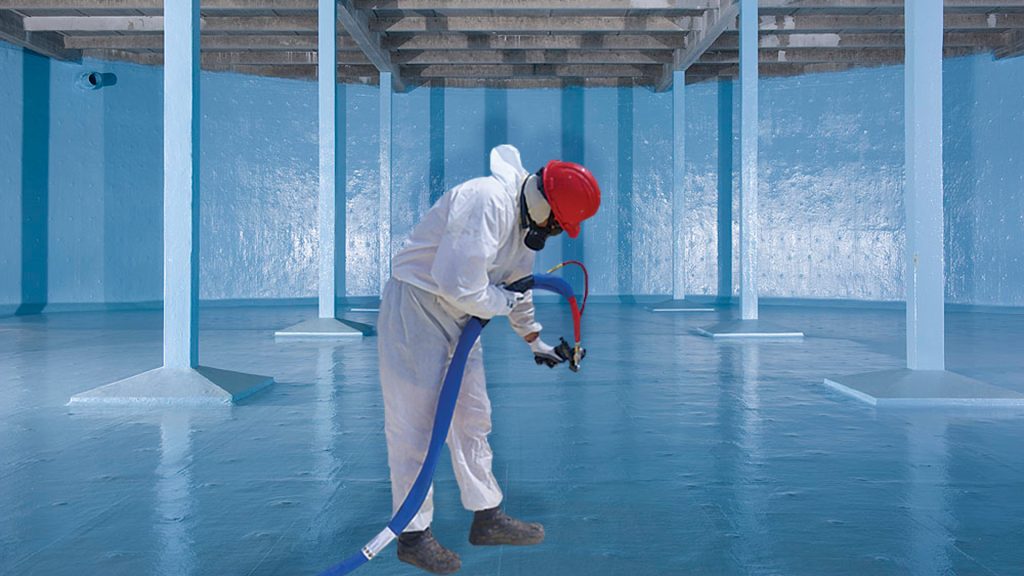

Benefits of Using Professional Protective Coatings Professional coatings offer a range of advantages, for surfaces. They are crafted to shield surfaces from factors and damage caused by use. These coatings can be applied to metals, plastics, concrete and other materials commonly found in industries like automotive and aerospace. Here are some key benefits of coatings;

Longevity; Professional protective coatings are engineered to be exceptionally durable and have a long lifespan. They safeguard surfaces from corrosion, rust, and other types of harm, thereby prolonging the longevity of the treated surfaces.

Chemical Resistance: These coatings are formulated to resist chemicals such as oil, gas, and solvents effectively. This resistance helps minimize contamination risk and protects the surface from deterioration.

Weather Protection; Professional protective coatings shield surfaces from weather elements like UV radiation and extreme temperatures. This protection helps prevent fading and cracking, ensuring that the surface maintains its appearance, for a period.

Ease of Maintenance; Additionally professional protective coatings simplify cleaning processes by offering a surface.

Professional protective coatings offer advantages, such, as reducing cleaning time and preventing stains or discoloration. They also enhance the appearance of surfaces by providing an matte finish improving aesthetics while ensuring protection.

In general professional protective coatings are durable chemical resistant and weatherproof making surface maintenance easier. Moreover they can enhance the appeal of surfaces.

TIPS FOR CHOOSING THE PROFESSIONAL PROTECTIVE COATING FOR YOUR PROJECT

When selecting a coating for your project it’s crucial to choose to avoid costly repairs and ensure longevity. Consider the projects location. Choose a coating, for that specific environment.When choosing a coating it’s crucial to consider the type of materials it will be applied to. Different coatings are tailored for surfaces so be sure to pick one that matches the materials you’re working with.

Additionally factor, in your budget. The cost of coatings can vary based on the type and application method. It’s essential to compare options and choose a coating that aligns with your budget.

Moreover think about the application process. Various coatings have application requirements so ensure you select one that suits the process you intend to use. Following the manufacturers guidelines is key to applying the coating

By taking into account your projects surroundings, budget and application method you can select the protective coating for your needs. A suitable coating can prolong your projects lifespan. Shield it from harm.

EXPLORING VARIOUS TYPES OF PROFESSIONAL PROTECTIVE COATINGS

coatings play a vital role in numerous industrial settings. These specialized coatings safeguard surfaces, against corrosion, abrasion, extreme temperatures and chemicals. Depending on the use case there is an array of professional protective coatings to choose from.

Epoxy Coatings; Epoxy coatings are an option, for safeguarding metal surfaces against corrosion and chemical damage. Typically they are applied in two layers with the layer ensuring adhesion and the second layer forming a film. These coatings come in colors. Finishes to cater to different needs.

Urethane Coatings; Urethane coatings are a high performance type of coating known for offering defense against abrasion, impact and wear. They are usually applied in layers each layer providing levels of protection. These coatings find use in marine environments.

Powder Coatings; Powder coatings consist of powder that is heated until it melts and adheres to the surface as a coating. They exhibit resistance to abrasion, corrosion and chemicals making them suitable for surfaces. Additionally powder coatings are available in a range of colors and finishes.

Fluoropolymer Coatings; Fluoropolymer coatings stand out as shields, against abrasion, corrosion and chemical exposure. Widely utilized in medical sectors for their performance and lasting protection qualities these coatings come in various colors and finishes.

Silicone Coatings; Silicone coatings serve as a layer known for their resistance, to heat and chemicals. They find use across industrial and commercial settings coming in an array of colors and finishes.

When it comes to selecting the coating there’s always a suitable professional option available. Opting for the coating can safeguard surfaces against numerous risks for years to come.

THE BENEFITS OF UTILIZING PROFESSIONAL PROTECTIVE COATINGS IN INDUSTRY

Protective coatings play a role in industrial operations, offering defense against corrosion wear and abrasion. From manufacturing and engineering facilities to power plants and refineries, they are indispensable. Professional protective coatings outshine DIY solutions in aspects like performance, longevity and cost effectiveness.

Professional protective coatings excel in performance due to leveraging cutting-edge technologies such as Fluoropolymer and zinc-rich formulations for heightened protection levels. These coatings are engineered to adhere to the substrate, ensuring bond strength and durability while resisting cracking, chipping, or peeling better than DIY alternatives.

Furthermore, professional protective coatings boast durability.

Professional protective coatings are crafted with the environment, in mind offering defense against elements like UV rays, chemicals and abrasion. This results in protection against corrosion wear and tear making them well suited for uses.

Moreover, opting for coatings can lead to long term cost savings. DIY solutions typically demand upkeep and repairs ultimately leading to higher expenses. In contrast professional coatings are engineered to have a lifespan and require maintenance, translating into substantial savings over time.

Additionally, professional protective coatings prioritize safety over DIY alternatives. These coatings undergo rigorous design and testing processes to meet safety standards for the well being of workers and the environment.

Professional protective coatings bring benefits to industries—ranging from enhanced performance to cost efficiency. With their extended durability and heightened safety features compared to DIY options they stand out as the choice for an array of industrial applications.

A Comprehensive Guide on Grasping the Expenses Associated with Professional Protective Coatings

Intended Audience; Professionals working in the protective coatings sector

coatings play a role in preserving surfaces across different sectors—from industrial machinery, to bridges and structures. However navigating through the costs involved in coatings can be daunting.

This guide offers an overview of the factors that can affect the pricing of a protective coatings project empowering you to make informed decisions, for your business.

Factors like the size and complexity of a project play a role in determining its cost. Projects entailing surface areas intricate details or multiple coating layers usually demand time, effort and materials, leading to higher expenses.

The location where the project takes place is another factor influencing costs. Projects in areas may incur travel expenses for technicians and higher shipping costs for materials.

The quality of materials used in a project directly impacts its cost. While high quality materials offer protection they also come at a price.

The application method chosen for applying the coating can also sway costs. Manual application methods are generally cheaper, than robotic processes.

Moreover, the complexity of a project can drive up costs well. Projects involving details, multiple layers of coatings or tight deadlines may necessitate time and resources ultimately resulting in increased expenses.

By grasping the aspects that may impact the pricing of coatings you can equip yourself to make well informed choices while planning for a project. Armed with knowledge and readiness you can guarantee the cost effective completion of your project.