Polyurea has earned a reputation as a coating material because of its toughness, flexibility, and quick drying time. It is versatile and widely used in sectors ranging from construction projects to home improvements. Polyurea offers precise solutions for various challenges, whether shielding pipelines from conditions or raising concrete structures.

Polyurea is widely used for coating pipelines because it protects against corrosion and wear caused by factors such as oil and water exposure and stressors like physical impact and chemicals.

Polyurea stands out from coatings due to its flexibility advantage in applications like pipelines that experience significant temperature changes, causing expansion and contraction over time. Unlike coatings that may crack or lose grip in these conditions, polyurea remains bonded and adjusts to the materials’ movements beneath it. This adaptability guarantees lasting protection without the hassle of repairs or reapplications.

Polyurea is known for its strength and quick drying time. It is crucial in pipeline work settings where time is of the essence and interruptions must be minimized for productivity and cost-effectiveness reasons.

Polyurea doesn’t just have advantages in pipelines; it’s also highly effective, in lifting applications too! As time passes by and various concrete surfaces like driveways or industrial floors start sinking or becoming uneven due to factors like soil erosion or poor compaction, the traditional solution involves time-consuming removal and replacement of the affected areas.. Thanks to polyurea-based concrete lifting techniques. There’s now a less disruptive alternative available!

When lifting, the polyurea or polyurethane foam injection method lifts the slab by filling the void beneath it and restoring it to its initial height level without any additional sinking issues once the foam cures and hardens. This provides stability and structural support for long-term use.

Polyurethane’s curing characteristics enhance the efficiency of lifting by enabling immediate use of the raised surface post-injection of foam and slab elevation process—allowing homeowners and businesses to quickly restore their properties without experiencing significant downtime or disruption to their daily activities due to the minimally invasive nature of the procedure that involves small injection points leaving almost no visible evidence of repair work—a sought after choice for residential and commercial properties seeking a solution for sinking concrete with minimal impact, on their routine operations.

Spray foam’s strong durability guarantees that the patched concrete stays firm and secure for some time. It adheres effectively to both the ground and the concrete surface to resist any shifting or displacement and prevent sinking issues. This enduring fix suits locations with pedestrian or vehicular activity and outdoor areas subject to varying weather patterns.

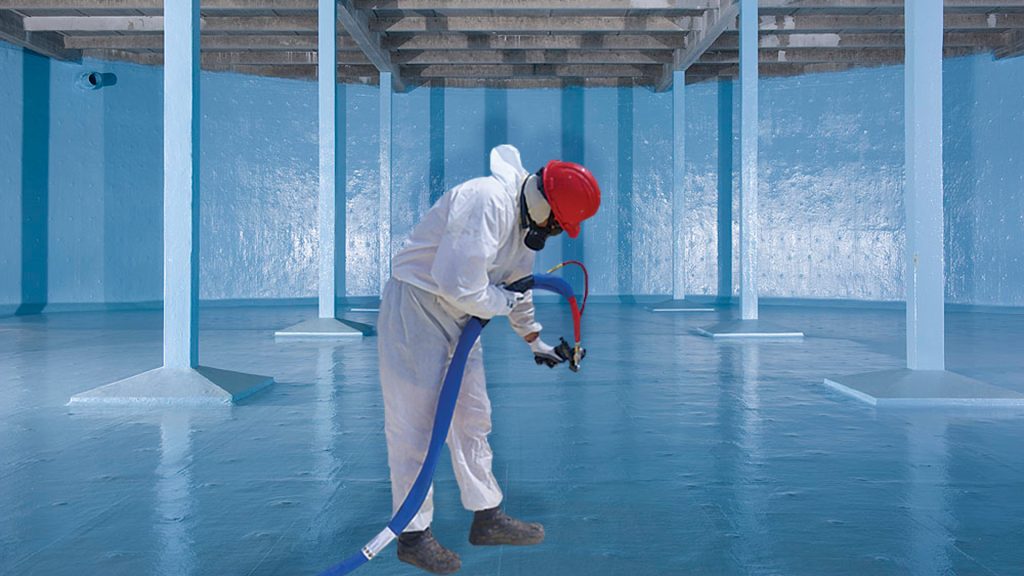

Polyurea plays a role in the sector by safeguarding surfaces against chemicals and extreme temperatures, like those found in manufacturing plants, oil refineries, or wastewater treatment facilities. They help shield equipment and storage containers from harm caused by corrosive substances or wear and tear.

Polyurea is widely chosen because it can create a layer without any seams for enhanced protection against water infiltration and safeguard the underlying surfaces from moisture-induced harm when used on rooftops or in water storage structures. This ability to prevent water penetration is especially beneficial in areas with rains or where leaks might weaken a building or infrastructure’s structural stability.

The efficacy of polyurea’s bonding to surfaces like foam, metal, wood, and concrete demonstrates its flexibility. This quality makes it a great choice for tasks such as coating a metal tank, waterproofing a base, or even repairing wooden structures effectively.

The process of applying the coating is quite simple. Does demand tools to guarantee proper adhesion and curing are achieved effectively? Spraying the material onto the surface results in a uniform layer that sticks securely in place. This technique provides management of the coating’s thickness to guarantee a protective barrier is evenly applied across the entire surface. After it has fully cured and bonded strongly to the material, polyurea maintains its durability and effectiveness over some time.

Polyurea has advantages in settings, too! It can protect outdoor decks and garage floors from deterioration due to use and exposure to moisture and chemicals. How convenient! Its durability means less upkeep is needed over time, a real plus for property owners seeking lasting protection without the hassle of repairs or reapplications.

With the progress in technology, col polyureaven is being utilized more and more in building and repair work. Its effectiveness in environments,p resisting wear and tear and offering durable shielding, guarantees that it continues to be a crucial substance for construction projects and industrial ventures. Whether its for pipelines or raising structures,, polyurea consistently achieves outcomes that satisfy the requirements of big scale enterprises as as well, as smaller home-based undertakings.

To wrap things up, the blend of strength, flexibility, and quick solidification in polyurea renders it a versatile substance suitable for uses. Whether safeguarding pipelines or raising sunken concrete, polyurea provides a long-lasting answer. Its capacity to adhere to surfaces and operate effectively in conditions guarantees its ongoing significance in enhancing and preserving infrastructure across multiple sectors.