Cities and municipalities manage infrastructure that must withstand constant environmental exposure, chemical deterioration, and physical wear. Roads, bridges, water treatment facilities, and public buildings all require regular maintenance, and traditional repair methods often lead to repeated failures and escalating costs.

By investing in training, equipment, and support, municipalities can take control of their own infrastructure maintenance, reducing costs and ensuring projects are completed on their schedules.

The Case for In-House Polyurea Application

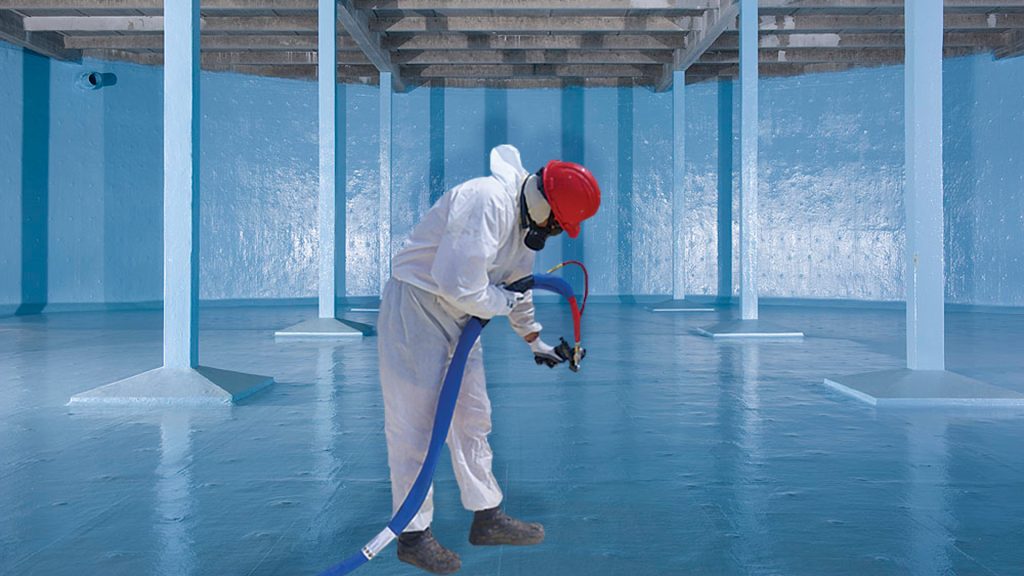

Polyurea coatings offer superior durability, chemical resistance, and flexibility, making them ideal for infrastructure protection. Cities that handle their own coating applications save significantly on outsourcing costs while maintaining the highest level of quality control. Whether sealing wastewater tanks, protecting bridges from corrosion, or waterproofing public buildings, polyurea provides a long-lasting solution.

To successfully implement an in-house coating program, municipalities need three essential components: proper training, professional-grade spray equipment, and ongoing support.

Training: Where Cities Can Learn to Spray Polyurea

A successful infrastructure maintenance program starts with proper training. Municipal employees must understand surface preparation, spray techniques, and the chemistry behind polyurea applications to achieve maximum durability.

ArmorThane’s Training Program provides a hands-on learning experience that equips city workers with the knowledge and skills needed to spray polyurea coatings effectively. The program covers:

- Equipment operation – Understanding proportioners, spray guns, and hose systems

- Surface preparation – Ensuring adhesion to concrete, steel, and other materials

- Application techniques – Controlling thickness, curing speed, and spray patterns

- Safety protocols – Proper handling of chemicals and protective gear

By completing this training, city maintenance teams gain the expertise needed to apply protective coatings efficiently and consistently.

Equipment: Spray Rigs Built for Municipal Projects

Having the right equipment ensures that municipal projects are completed efficiently and to the highest standards. ArmorThane offers mobile spray rigs designed for infrastructure applications. These rigs are fully equipped with:

- High-performance proportioners that precisely mix and spray polyurea

- Heated hose systems to maintain proper viscosity and spray consistency

- Generator and air compressor units for self-sufficient operation on-site

- Climate-controlled storage to keep materials at optimal temperatures

With a mobile spray rig, municipalities can move between job sites seamlessly, applying protective coatings to bridges, pipelines, parking structures, and more.

Ongoing Support: Ensuring Long-Term Success

Even with proper training and equipment, municipalities need continued technical support to troubleshoot issues and maintain their spray systems. ArmorThane provides:

- Technical assistance – Expert guidance on application challenges

- Equipment servicing – Maintenance programs to keep rigs running efficiently

- Material supply – Access to high-quality polyurea coatings tailored for infrastructure use

By partnering with ArmorThane, cities gain a long-term resource for their infrastructure maintenance needs.

Conclusion

For municipalities looking to cut costs, improve efficiency, and extend the lifespan of public infrastructure, in-house polyurea application is a strategic solution. With training, professional-grade spray rigs, and dedicated support, cities can take full control of their maintenance projects while ensuring the highest level of protection for their assets.

ArmorThane provides everything needed to establish a successful municipal coating program, from hands-on training to advanced equipment and ongoing expertise. Investing in these resources allows cities to build resilient infrastructure while reducing long-term maintenance expenses.