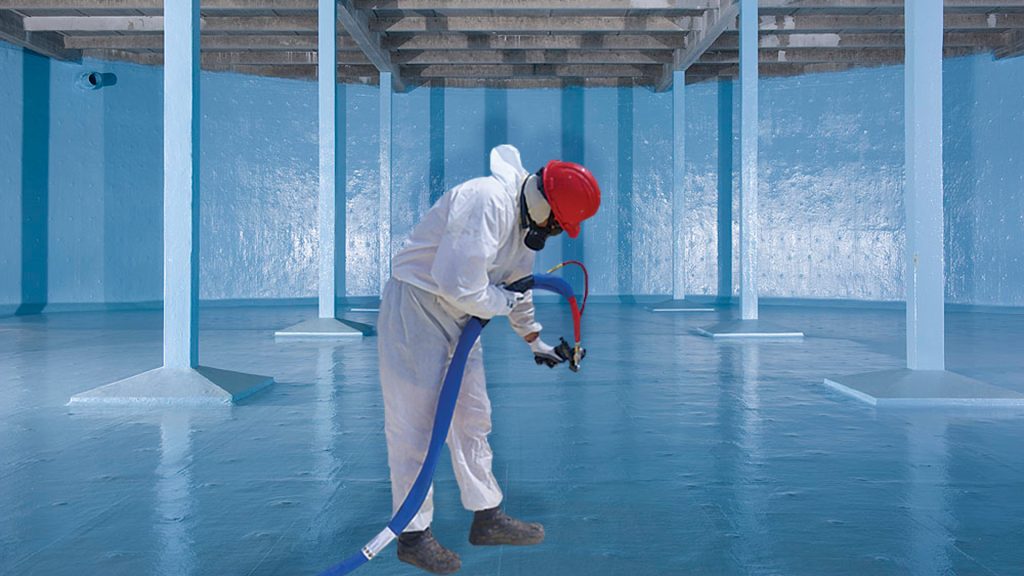

Polyurea deck coatings are increasingly popular for their unique and highly modular physical properties. They’re capable of protecting decks made of wood, concrete, and other substrate materials from constant use, abuse, and exposure to the elements. With demand surging, prospective applicators have a new, highly profitable reason to start a new business providing polyurea deck coatings to both residential and commercial clients. However, the process of applying high-performance polyurea that can actually impart these benefits to surfaces requires specialist knowledge and considerable practice. Professionals looking to specialize in polyurea spray applications can turn to comprehensive training and certification programs, where they can learn the ins and outs and get equipped with the right tools for the job. But what exactly should you expect from a polyurea deck coating training program, and why is such training so valuable?

WHAT SHOULD YOUR DECK COATING TRAINING PROGRAM COVER?

A well-structured polyurea applicator training program blends classroom theory with hands-on practice to build a complete skill set for the applicator to deploy wherever they’re needed:

- Equipment Operation & Maintenance: Polyurea is applied with sophisticated plural-component spray rigs that precisely heat, mix, and pressurize the two components before they’re ejected from the nozzle of the spray gun. Training covers how to set up and operate proportioning pumps, spray guns, and related equipment, as well as how to perform routine maintenance and repairs to keep the system running reliably. Hands-on modules often include tearing down and reassembling spray guns or pumps to help applicators get comfortable with the inner workings of their machinery.

- Surface Preparation and Priming: All successful polyurea applications begin with meticulous surface prep, a part of the process just as important as the deck coating installation itself. Trainees learn to assess and prepare different substrates (concrete, steel, wood, etc.), including cleaning, repairing defects, and achieving the proper surface profile (e.g. via abrasive blasting or grinding). Quality courses emphasize how to identify substrate conditions (moisture content, existing coatings) and when to use primers or other treatments to create optimal adhesion of the polyurea deck coating. Mastering surface preparation is essential because even the best polyurea formulation will fail if applied over a poorly prepared deck.

- Application Techniques: Proper spray technique is extensively taught and practiced; applicators are trained on controlling the spray gun angle, distance, and movement speed, as well as overlap patterns, to achieve a uniform coating thickness without holidays or runs. Given polyurea’s fast set time, instructors demonstrate techniques for handling complex geometries (edges, corners, vertical surfaces) and maintaining a wet edge. The training often involves live spraying exercises where participants can refine their technique under expert supervision, and it’s these exercises that build the muscle memory needed to apply polyurea consistently and avoid common mistakes like uneven buildup or overspray.

- Environmental Monitoring: Environmental conditions have a big impact on polyurea system outcomes, so quality training programs teach how to monitor and control the application environment with as much precision as possible. Trainees learn to measure ambient temperature, humidity, and substrate temperature, and to calculate dew point – all factors that determine whether it’s safe to spray and how the coating will cure. Courses often stress the use of a job log or environmental checklist to document conditions for each project, as knowing how to interpret and respond to conditions (such as waiting for a substrate to dry or adjusting machine settings for cold weather) is an important part of the applicator’s judgment.

- Safety Practices: Safety training is a core component of any applicator course, regardless of the material, use case, or environment. Participants are taught about the hazards of polyurea precursor chemicals (like isocyanates) and the strict safety measures required, including personal protective equipment (PPE) and engineering controls. They learn how to select and use respirators correctly, what protective clothing is needed, and how to ensure adequate ventilation in enclosed spaces. Electrical and fire safety (since heaters are used in equipment and flammable chemicals may be present) are also often covered. A good training program will instill a safety-first mindset, seeing that graduates not only know how to spray, but also how to do so without endangering themselves or others.

- Troubleshooting and Quality Control: Even with good training, things can go wrong on a job – so courses teach applicators how to troubleshoot and solve problems in the field. This includes recognizing symptoms of improper mix ratio or equipment issues (for instance, if the spray pattern is off or the coating isn’t curing correctly) and knowing how to correct them. Trainees also learn what to do if the finished coating shows defects like pinholes, blisters, or poor adhesion – often by tracing back to surface prep or environmental issues and addressing the root cause. In addition, training covers quality assurance tests such as checking film thickness with gauges, adhesion pull-off tests on sample areas, and other verification methods to ensure the coating meets the specification.

HOW TO CHOOSE A REPUTABLE DECK COATING TRAINING PROGRAM

For professionals considering polyurea training, selecting the right program or provider is an important step. Not all training courses are equal in depth and quality, so you will want to evaluate your options carefully based on the following criteria:

- Curriculum Content: Look for programs that cover all the essential topics discussed above – from equipment and surface preparation to safety and troubleshooting. The curriculum should be comprehensive and technically detailed, rather than a cursory overview; be cautious of courses that seem too short or overly focused on selling a particular product, as they may not provide the well-rounded education you need.

- Instructor Expertise: The quality of instruction matters a great deal. Ideally, the course should be led by seasoned experts in the polyurea or protective coatings industry who have significant field experience. Training organizations often highlight that their courses are taught by industry leaders, which is a good sign; in fact, some of the most respected programs are headed by leading experts who teach participants how to manage all aspects of the job from equipment to substrate conditions and project specifications. An experienced instructor can impart practical insights and insider tips that you won’t find in manuals.

- Hands-On Practice: Polyurea application is a hands-on skill, so the training should include plenty of practical exercises. Your program should offer live demonstrations so that you get to practice spraying polyurea and handling the equipment yourself, under guidance. Applying what you learned in a controlled setting is crucial – it builds confidence and muscle memory, so always steer away from any training that is 100% classroom or online for this trade; you’ll want a chance to get familiar with the spray gun, mix settings, and real polyurea material during the course.

- Certification and Recognition: Consider what qualification you receive at the end of the training. Does the course include a certification exam or a performance assessment? Programs backed by well-known industry associations or leading manufacturers tend to issue certificates that are recognized and respected in the industry. Earning a certification from a reputable program will bolster your professional credibility, so it’s worth checking the reputation of the certificate you will obtain.

- Safety and Support: Evaluate how much emphasis the training places on safety and whether the provider offers any ongoing support. A good training program will treat safety training as non-negotiable, and priority number one (covering PPE, equipment safety, etc., as discussed). Additionally, some providers offer technical support hotlines, refresher modules, or resources for alumni, and it can be beneficial to have access to expert advice even after you complete the course, especially when you encounter a tricky project in the field. Reading reviews or testimonials from past participants can also give insight into the program’s real-world value and whether it lives up to its promises.

By carefully choosing a high-quality training provider and attaining certification, professionals in the coatings industry can expand their skill set and confidently take on polyurea deck coating projects. But now armed with the knowledge of what comprehensive polyurea training entails and why it matters, you can make an informed decision to advance your career as a certified polyurea deck coating applicator.