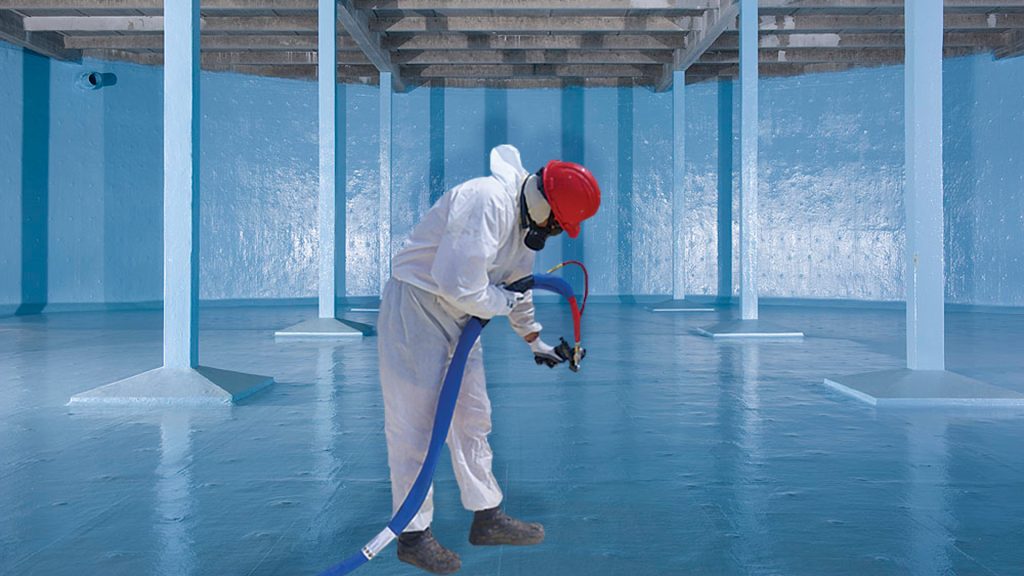

Flat roofs fail for the same two reasons, again and again: trapped moisture and movement the membrane was never asked to handle. Polyurea solves those problems when it is allowed to do what the chemistry was designed for, which is to form a seamless, elastomeric skin that stays bonded even when the deck flexes. Before a single drum is warmed, an installer has to understand why the product works, not just how to spray it. Coatings Academy’s mission has always been to close that knowledge gap by translating laboratory lessons into job‑site language.

WHY POLYUREA IS DIFFERENT

Most liquid membranes use water or solvent as a carrier; they need evaporation time before they build strength. Polyurea reacts internally, reaching set within seconds, faster than rain can land and faster than dust can settle. This speed is not magic; it is the direct result of an amine‑isocyanate reaction that forms long, flexible urea linkages. Those links behave like molecular springs, stretching under load and snapping back without tearing.

MOISTURE MANAGEMENT STARTS BELOW THE DECK

A low‑slope roof has no place for water to hide, yet water hides anyway—in insulation joints, under a mechanically fastened base sheet, or in yesterday’s dew that did not quite burn off. The best defense is patience: keep the deck dry long enough to prime, then keep the primer open just long enough to bite without flashing off. One overlooked tactic is to roll primer slightly past the spray line so that overspray never meets raw concrete, a simple edge detail that buys years of service life.

Watch for early warnings. A whiff of carbon dioxide in the spray plume often signals moisture reacting with free isocyanate. “Rice crispy” crackling underfoot the morning after a spray means foam has formed below the film. Catch either sign early and a localized grind‑and‑repair can prevent a wholesale re‑coat.

ADHESION IS A SYSTEM, NOT A NUMBER

Spec sheets quote jaw‑dropping pull‑off strengths, but field adhesion depends on film build, surface profile, and cure temperature working together. Even a perfect anchor pattern is wasted if overspray cools ten degrees on a breezy parapet and gels prematurely. Experienced applicators stagger spray passes so the hot ribbon of the second pass reheats the edge of the first, fusing the two into a single monolithic layer instead of a cold lap.

LIVING WITH THERMAL CYCLING

Every roof moves, but metal and concrete move differently. Polyurea’s reported elongation, often above 400 percent, tells only half the story; its low glass‑transition temperature is what allows that stretch to happen at winter dawn without the brittleness that shatters acrylics. Bridge the expansion joints below, and the membrane will ride out the change in length without wrinkling. Ignore them and the coating will telegraph the split on the first hot afternoon.

QUALITY CONTROL YOU CAN HOLD IN ONE HAND

Inspection gear for a polyurea roof fits in a jacket pocket: a wet‑film gauge, a calibrated IR thermometer, and a pair of machinist’s calipers for dry‑film checks. A simple routine, like a film check at 10 % of passes and a temperature check every half hour, catches nearly every preventable defect. The best crews add a log of hose pressure and temperatures; over a season those notes become a playbook for every deck and every micro‑climate in a contractor’s territory.

Polyurea is not a “spray and pray” miracle, but a high‑speed chemistry that rewards disciplined preparation. Control moisture first, follow with conscientious film builds, and respect the thermal life of the roof. Master those fundamentals and the membrane will do what it already knows how to do: stay waterproof, stay flexible, and stay put.