Traditionally, polyurea businesses have been forced to be built around location. You had to choose your location well and build the business around the store itself. However with the invention of the mobile coating unit (or polyurea spray rig), things are totally different. Spray rigs have opened up wonderful new application opportunities that most coating companies do not even consider. With a properly fitted-out mobile unit, you can easily turn a parking lot, a construction site, or an industrial yard into a money-making machine. Those entrepreneurs who can think beyond the truck bed and the factory floor can create unique positions where there is still little competition.

Coating the Unconventional

Most polyurea businesses are rather conventional. They paint the beds of trucks, perform industrial floor coatings, and fix leaky basements. These services are quite lucrative, but polyurea is best used in the areas where other coatings are powerless. Those who understand this shift and act on it move into markets that other companies do not even attempt to penetrate. An amusement park is a facility that is subjected to Wear and Tear. Roller coasters are subjected to a lot of stress in their normal operation. Water slides are exposed to friction, sunlight, and chlorine treatment.

Walkways tend to break due to a high concentration of people walking on them. Conventional repair methods are usually time consuming and expensive as the structures have to be closed down for repairs. A mobile polyurea rig is a better way of doing this. The technician can do minimal preparation and then apply a single layer of protective coating that is long lasting, resistant to wear, chemicals and extreme temperatures. The park achieves this while minimizing the down time of its expensive structures.

Similar opportunities exist for stadiums and arenas. Their seats, railings and concrete steps need periodic maintenance. Polyurea’s short set time guarantees that applications can be done at night especially during peak seasons. It is very durable and is ideal for use in high traffic areas such as locker rooms and player tunnels. Owners are always interested in ways that can help them cut on the costs of maintenance without affecting the service life.

High-Risk, High-Reward Applications

Tunnels, bridges and marine structures are among the structures that are beyond the scope of normal coatings. These surfaces are exposed to water, salt and temperature variations. Engineers look for materials that are corrosion resistant, flexible and can be used on various substrates. Those applicators who are willing to work in these conditions are given attractive contracts.

Subway stations that are located above the ground have problems with water leakage. The use of polyurea to seal these structures ensures that water does not seep through and cause damage. A properly applied layer increases the service life of concrete and steel without requiring frequent repairs. The capability to operate in confined spaces and adhere the finish to the varying shapes and sizes makes polyurea a suitable material.

Severe conditions also affect offshore oil platforms and naval ships. Salt water is adverse to metals since it leads to corrosion that is costly to repair. Ship decks, bulkheads and equipment housings are better coated with polyurea. The material’s impact resistance protects against dropped tools and equipment strikes. Those who are willing to take their rigs out to sea will never lack work in this area as far as durable coatings are concerned.

Small-Town, Big-Market Thinking

The big cities provide a steady source of business, but the rural areas are still unexploited. Some of the communities out there do not have access to specialized coating services. Farmers, ranchers, and other small-town contractors face issues that polyurea solves. A mobile applicator who is willing to travel will not lack work to do.

The dairy farms and livestock facilities are exposed to a lot of moisture and bacteria growth. Wooden stalls, concrete feed bunks, and metal equipment are prone to deterioration in adverse conditions. Such seals cannot last long without being reapplied. Polyurea forms a single layer seal that is nonporous, resistant to moisture, acids, and abrasions. Farmers who invest in long-term solutions can only reap the benefits in the long run.

In colder climates, road maintenance departments face another problem – the freeze-thaw cycle. Each winter, the asphalt and concrete is cracked. It only gets worse. Many small municipalities do not have enough money to replace the roads frequently. A mobile unit that can apply polyurea based repair solutions is a cost effective option. These treatments seal cracks and strengthen potentially failing locations to increase the service life of roads and sidewalks.

Speed Matters

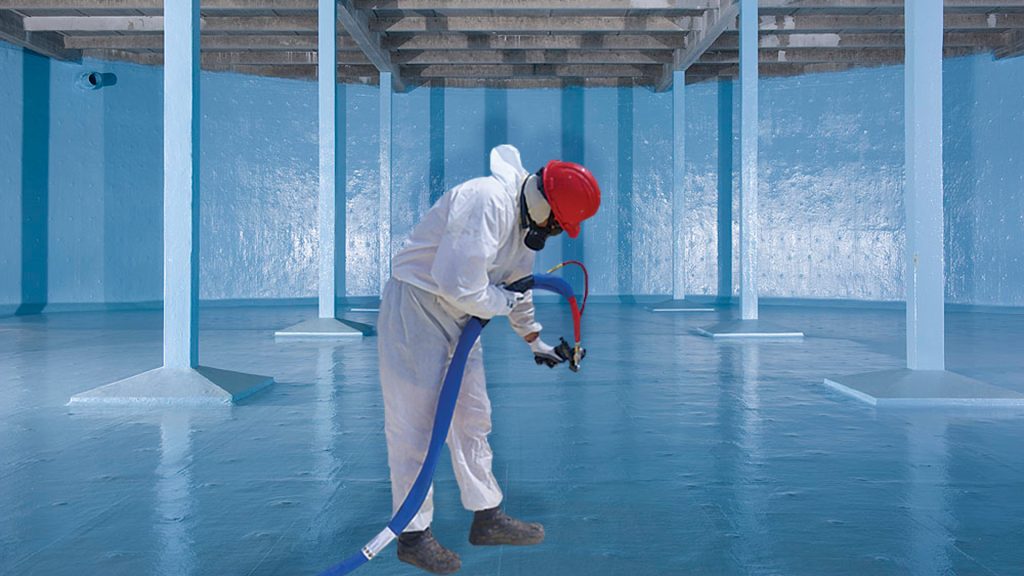

Construction projects are always time driven. Contractors require solutions that can minimize the downtime without sacrificing the durability. Most of the conventional waterproofing methods have long curing time and require application of more than one coat. This is where polyurea comes in handy since it can be applied and set very quickly. Mobile applicators who know the construction schedule will get repeat business.

Foundation waterproofing is a good example. Most builders use sheet membranes or tar based coatings. The former method is difficult to apply and the latter is liable to leak at the joints. Polyurea sticks well on concrete and forms a smooth, flexible seal. Since it takes only a few seconds to cure, the backfilling can be done on the same day. Builders who switch to polyurea based waterproofing can reduce the time frame of a project without jeopardizing the quality of the project.

Similar benefits can be seen in pool construction. Tile and plaster coatings take several days to apply and cure. A polyurea coated pool shell is a rubber like material that is resistant to chemicals, has a high resistance to impact and is flexible. With this method, contractors can finish more projects and open more pools in a single season.

The Road Ahead

A mobile polyurea business is a versatile business. Operators can work in the market of their choice, set their prices according to the market and build their reputation in sectors that value the product durability. Those who try to find particular uses of the product will have a competitive edge over their competitors who aim at general use. The work exists. The only challenge is to understand where polyurea can be most effective.