Polyurea is well known for its strength, flexibility, and quick cure time, making it a popular choice across industries like construction and automotive. A key factor contributing to the effectiveness of polyurea is its bonding properties. The ability of polyurea to adhere to a surface is crucial to ensuring the durability and reliability of coatings. Delving into the science behind polyurea bonds sheds light on why this material safeguards surfaces against mechanical pressures.

Understanding Adhesion Basics

Adhesion refers to the process of two materials sticking together, the polyurea and the substrate, in this discussion. This bond keeps the coating securely attached to surfaces for lasting protection. The strength of adhesion relies on factors including the properties of polyurea, the characteristics of the substrate, and application conditions.

Chemical And Physical Interations

Adhesion involves both chemical and physical interactions. Physical adhesion occurs when polyurea mechanically grips the surface by filling in pores or irregularities. On the other hand, chemical adhesion entails forming bonds between polyurea and the substrate through mechanisms like covalent bonds, hydrogen bonds, or van der Waals forces, depending on the materials involved. To ensure adhesion, polyurea must establish chemical bonds with the surface. This unique bonding approach allows polyurea to adhere effectively to surfaces like concrete, metal, wood, and plastic.

The Importance Of Proper Prep Work

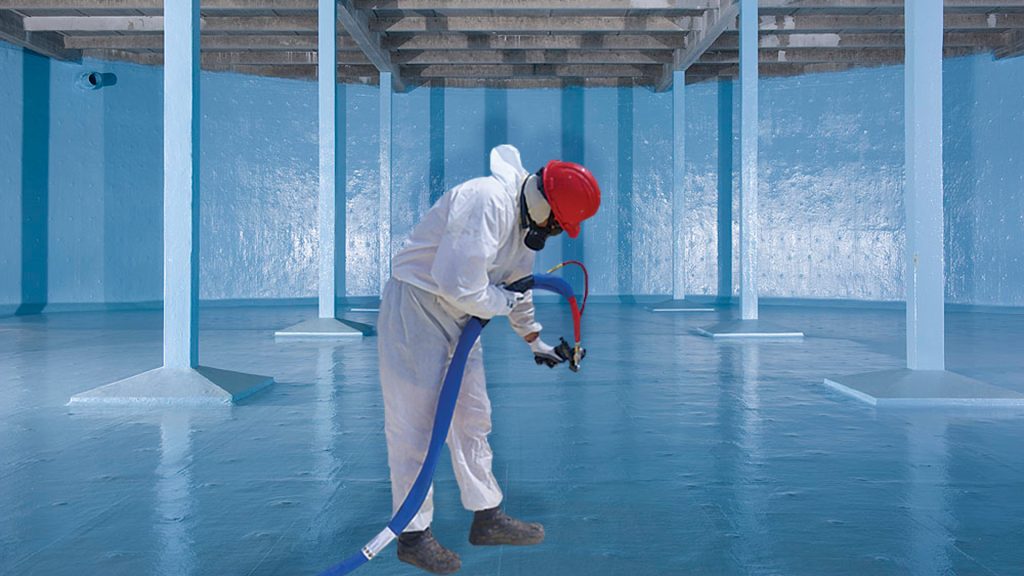

The key to achieving a bond lies in surface preparation before applying polyurea. Properly preparing the substrate is critical for maximizing the adhesion potential of polyurea. This involves cleaning the surface to eliminate any impurities, such as dirt, oil or rust that could hinder adhesion. Techniques like blasting, sanding or chemical cleaning are commonly used to create an rough surface that enables polyurea to adhere better.

The roughness of the surface significantly influences adhesion. Roughening the substrate increases the surface area for polyurea to bond with. This allows the material to seep into crevices and pores on the surface,, creating an interlock that strengthens the bond. This mechanical interlocking is particularly crucial on surfaces like metal where relying solely on bonding may not be adequate, for ensuring strong adhesion. Surface roughness and chemical compatibility between the polyurea and the substrate are important. For instance, some metals might need a primer to improve chemical bonding. This primer acts as a layer,, enhancing how the polyurea and substrate interact and ensuring that the coating sticks properly.

Environmental Effects

Environmental elements like temperature and humidity play a role in how polyurea sticks. Polyurea is a type of elastomer that sets with heat so its qualities are affected by the temperature during application and curing. To get adhesion the substrate temperature should fall within a range typically between 60°F and 90°F depending on the type of polyurea used.

If the substrate is too cold, the polyurea might not spread well on the surface, resulting in adhesion. On the hand if its too hot the polyurea could cure fast and fail to create a strong bond with the surface. Humidity levels can also influence adhesion issues when applying polyurea to absorbent surfaces like concrete. High humidity can trap moisture in the substrate, causing problems, like blistering or separation after curing.

To ensure a bond, it’s important to manage the factors during the application process. This involves monitoring the temperature and humidity levels and adjusting the application method as necessary to guarantee that the polyurea adheres well to the surface.

Quality and Performance Evaluation through Adhesion Testing

Testing adhesion is crucial for assessing how well a polyurea coating performs. This evaluation is typically carried out in both controlled settings and real-world scenarios to determine the bonding effectiveness of polyurea to surfaces. One common way of testing adhesion is through a pull-off test, where a device applies force to detach the coating from the substrate, measuring the force needed for separation as an indicator of adhesion strength.

Another testing method is the the peel test, in which the coating is peeled off from the substrate at an angle and speed. This test helps measure the force required for peeling and identifies any points in adhesion. Both pull-off and peel tests offer insights into how a polyurea coating performs, enabling manufacturers and applicators to verify its performance in real-world conditions.

These tests help uphold quality standards when applying polyurea coatings. By ensuring that the coating has bonded correctly, manufacturers can be assured that the polyurea will offer the intended level of protection and longevity.

Enhancements in Polyurea Adhesion

With the rising demand for polyurea, research and development are concentrating on enhancing its ability to stick firmly. One aspect of progress involves creating formulations of polyurea that boost chemical bonding with surfaces. These formulations might contain additives or modifiers to increase the reactivity of the polyurea,, enabling it to create connections with surfaces that’re typically difficult to coat.

Improvements in primer technology are also enhancing adhesion. Primers are being designed with compatibility and enhanced bonding properties to ensure that the polyurea sticks effectively, even under less-than-ideal circumstances. These advancements are broadening the range of applications for polyurea, making it a feasible choice for coating surfaces.

The application process is also developing, introducing tools and methods that enhance the accuracy and uniformity of polyurea coatings. Automated spray systems, for instance, enable application, guaranteeing that the polyurea is applied evenly and at an ideal thickness for strong adhesion. These advancements are pushing boundaries on what can be achieved with polyurea, elevating its value as a material for coatings.

In summary, the success of polyurea as a coating is deeply rooted in the science of adhesion. Professionals can enhance the bonding of polyurea to surfaces by considering factors like surface preparation and environmental conditions. With advancements and innovations, the adhesion capabilities of polyurea are expected to improve, broadening its applications and strengthening its position as a leading protective coating globally. The meticulous combination of chemical interactions, testing, and quality assurance measures ensures that polyurea remains a dependable solution for safeguarding surfaces in even the most challenging settings.